DAS Energy Technology

Revolutionized photovoltaic innovations through research & development

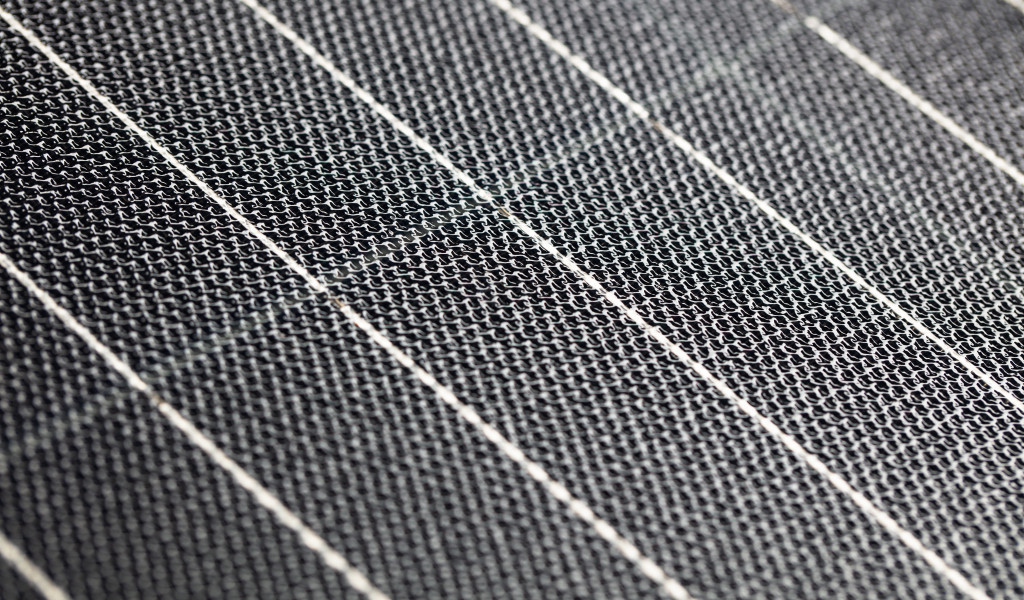

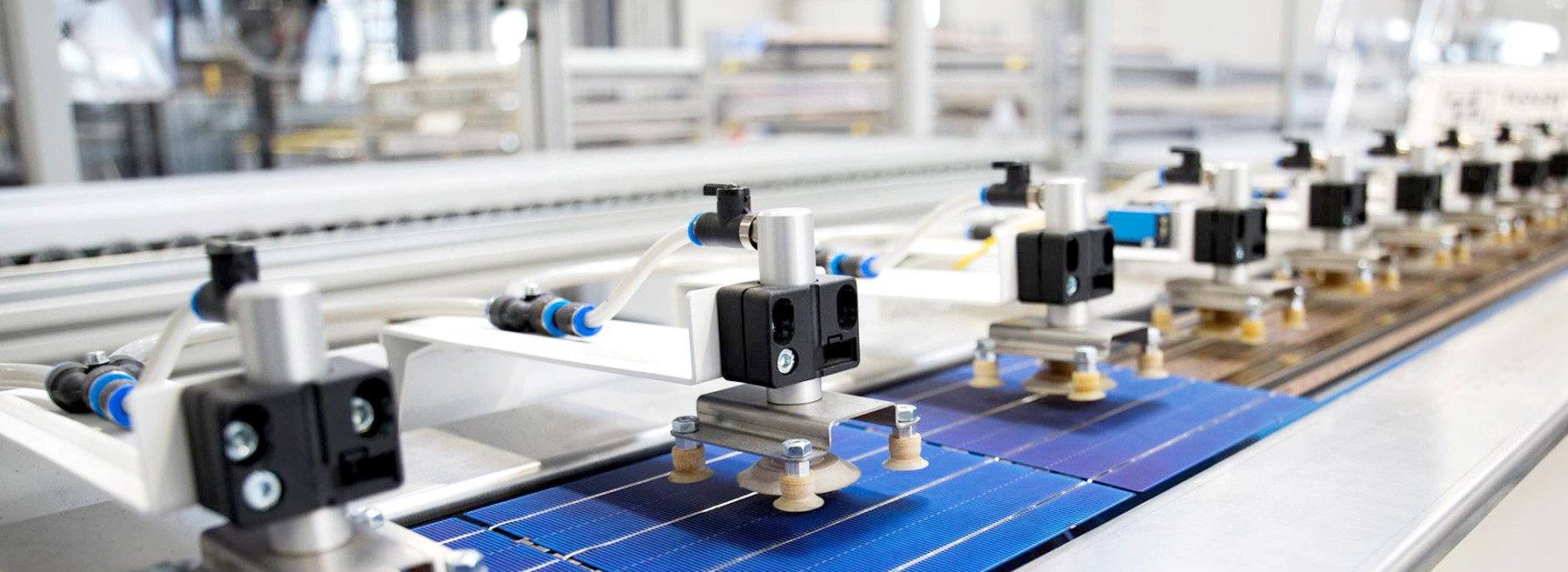

The patented technology used in our modules was developed by DAS Energy in Austria, and consists primarily of a proprietary fibreglass reinforced plastic core (pre-preg). This layer is found above and below the cell, and is primarily responsible for the flexibility and stability of the DAS modules. The material ensures that the photovoltaic modules are significantly lighter, thinner and more flexible than traditional PV panels. At just 3.8 kg/m2, they are much lighter than traditional heavy glass panels, and their flexibility allows them to fit the contours of curved surfaces. Our photovoltaic modules are non-reflective, as they do not use any glass. Traditional monocrystalline cells are used in the panels.

Our products offer high energy output while being ultra-lightweight and flexible. They weigh just 3.3 kg/m2 and therefore vastly reduce the requirements for substructures. The modules' flexibility means that they can be mounted in a variety of ways: on all types of roofs including waterproof membranes, metal roofs and many other types of roofing. In particular, DAS Energy modules can simply be glued to the roof, as well as being affixed using screws, rivets, magnets or grommets.

40 Years Performance Guaranteed

Our first certified PV modules have been in use since 2014 without issues. As the fibreglass materials used by us come from the aerospace industry and have withstood enormous wear in that capacity, we offer a 40-year performance guarantee for building-integrated and building-applied modules (85%). Our modules have been tested in numerous environments (UV resistance, climatic chamber etc.).